Women on Wings supply chain management expert Margo Zuurveld-van Oosterom contributed to this article on standard operating procedures.

Streamlining operations, enhancing quality and freeing up time from constant small issues are all part of a method for smart growth.

The method: Standard Operating Procedures (SOPs). We are going to share about what to expect with SOPs.

SOPs are game-changers. Every time.

Our social enterprise partner, Tamul Plates Marketing Private Limited (Tamul), recently experienced the power of SOPs firsthand. Chief Impact Officer Debaleena Ray, Co-founder and COO Manabendra Pathak and CEO Arindam Dasgupta, along with their team, thoroughly examined their processes during an assignment with Women on Wings expert Margo Zuurveld-van Oostrom and senior business consultant Chanakya Mehta.

We collaborated to map Tamul’s complete value chain, from raw material procurement and washing to the delivery of finished products. Margo emphasized that if there are more than 15 processes in an activity, a new SOP is required.

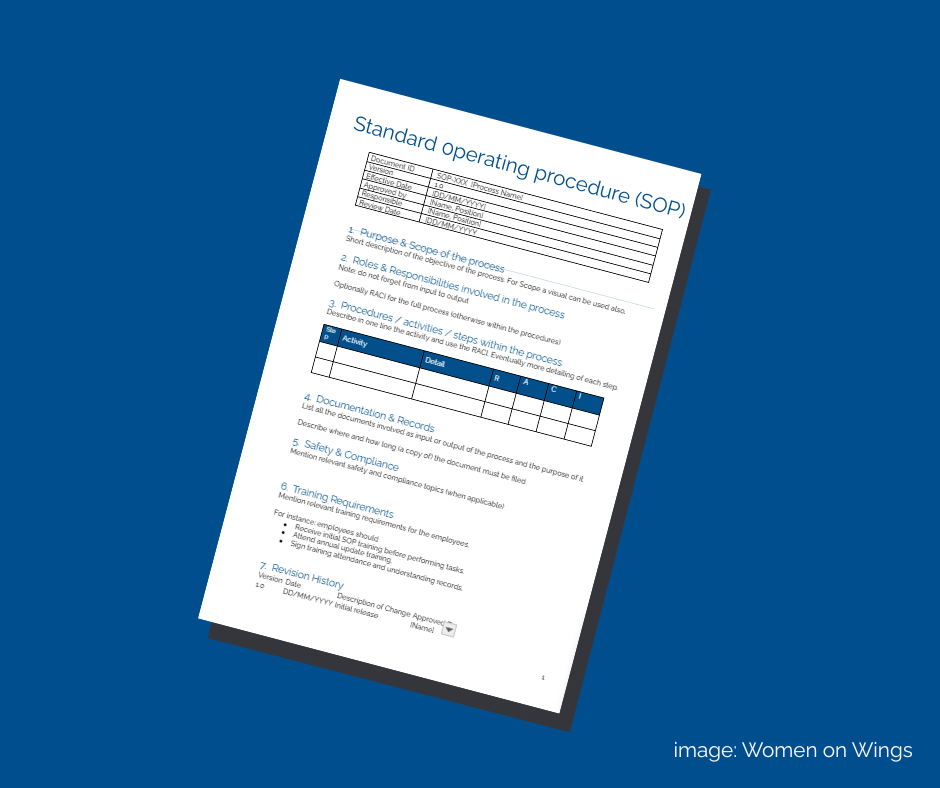

An example of an SOP template that Women on Wings shared with Tamul Plates

Why do SOPs matter to your enterprise?

Why bother with SOPs, especially now? The current economic climate and evolving consumer demands mean efficiency and consistency are more crucial than ever. Customers expect quality, and a lean, well-run operation is your competitive edge.

They matter because they mean clarity. No more guesswork, no more “how do we do this again?” moments.

Here’s what to expect with SOPs:

- Consistency and quality: Tamul Plates defined clear processes and performance indicators, ensuring consistent, high-quality products, deliveries and customer interactions. This translates directly to a reliable product and a competitive edge. For your enterprise that translates directly to a reliable, high-quality product and competitive edge. When processes are clear, work gets done more efficiently. This saves time, reduces errors, cuts waste and improves the overall flow.

- Trust and loyalty: Consistent adherence to SOPs, including dedicated quality control, guarantees customers receive the same excellent product every time, building trust and loyalty.

- Knowing who does what: The RACI model defines roles and responsibilities, eliminating confusion and empowering teams by clarifying who is Responsible, Accountable, Consulted, and Informed for each task. Game-changer, right?

- Documentation: It helps with documentation of different stages of the value chain, to keep track of what happened and when. It helps with quality control for non-conforming products

- Resources: SOPS clarify resource requirements, such as staffing and necessary supplies like gloves, helmets and masks.

- Safety and compliance: SOPS help us in understanding compliance and safety related to all processes.

- Team members assimilation: SOPs are your instant training manual. No more relying on hive knowledge or endless re-explanations. Tamul Plates found that this process deepens their understanding of their own business, and you will too.

Khina collects raw materials from villages which she produces biodegradable tableware and packages them for Tamul Plates

Invest time in your enterprise’s future for clarity and profit

Defining SOPs is a team effort, building a solid foundation for business expansion into new markets or with new products.

Tamul Plates produces compostable tableware from areca palm sheaths using leaves that would otherwise be discarded after the betel nut (the plant’s fruit seed) is harvested. They distribute domestically and abroad. They invested the time to build a robust SOP system, and it will pay dividends.

Isn’t it time you invested in giving your own venture the clarity and consistency it deserves? Your future self (and your profit margins) will thank you.